Truck Wheel Stopper / Vehicle Restraint

Truck Wheel Stopper / Vehicle Restraint

HALT ST

BROSIS HALT ST represents a new system for safety of vehicles docked at loading bays during loading / unloading operations. Easy to use, BROSIS guarantees a safe and continuous function and is at the forefront when it comes to comply with standards in force. This system consists of a series pneumatically lifted wedges which are placed near the back wheels of the vehicle already in loading/ unloading position.

This prevents any accidental movement which would create danger for people handling the goods.

Avoid Risk

- Unexpected departure of the truck

- Progressive movement of the trailer

- Unexpected departure of the truck and falling over of the forklift driver. Cause to No communication between the bay operator and the truck driver

- Progressive movement of the lorry and fall over of the forklift driver

Main Advantages

- Immobilize all types of trailers

- Simple and reliable

- Make the operation automatic

- Can be installed in any conditions (new building, existing levelers and wheel guides, …)

- Simple preventive and curative maintenance

- Enslavement with the loading bay door.

- Load capacity – 40 tons.

Operations

Principle: loading bay door “open”, chocks raised, loading bay door “closed”, chocks in lowered position

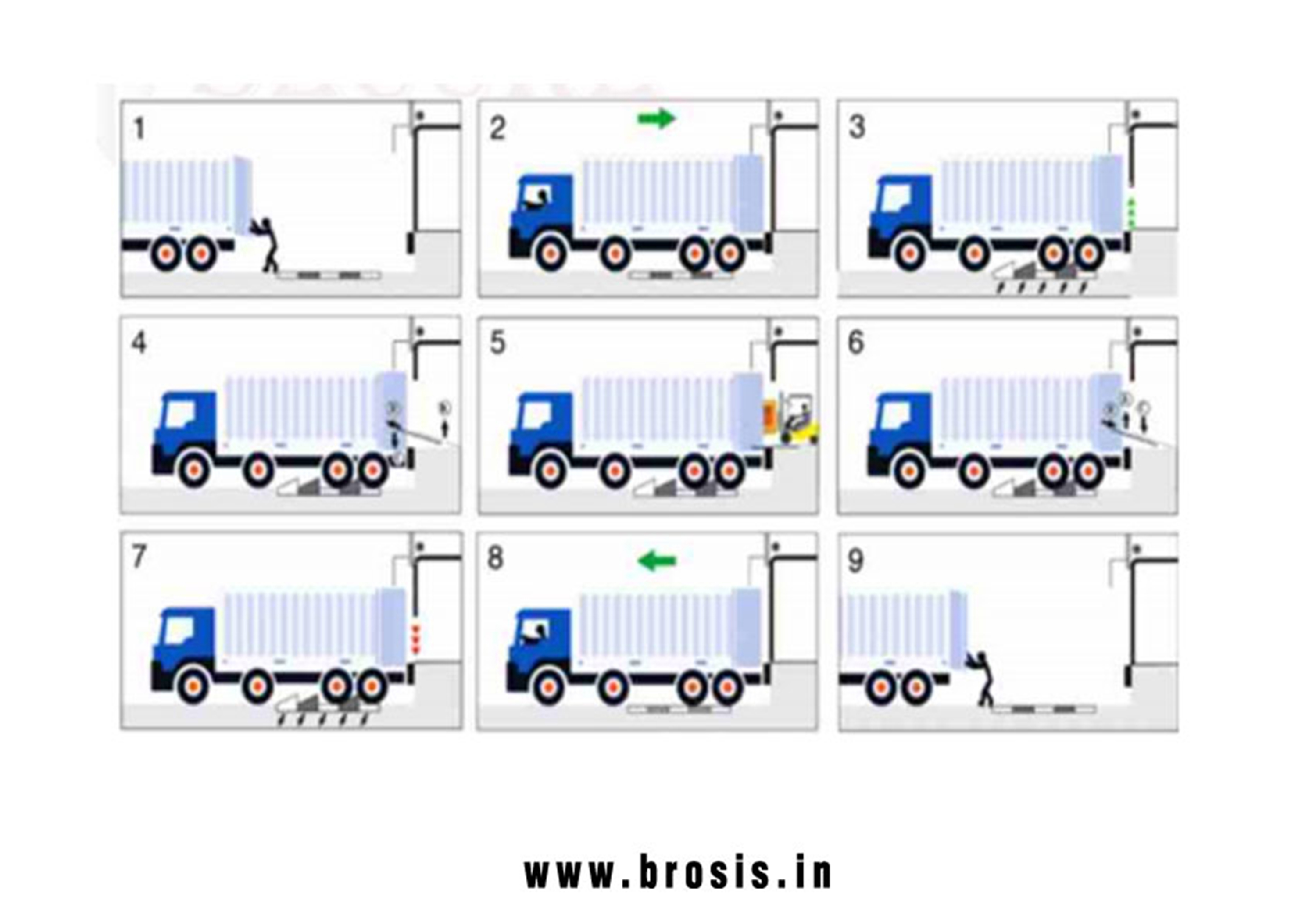

The Usual Working Procedure

1-2.The lorry arrives and reverse over the loweredchocks.

3.The bay operator open the door/barrier lifting upautomatically the chocks. The lorry is immobilized.

4-5.Once the chocks are raised, the forklift driver is allowed to position the dock leveler. The loading

and unloading operations can proceed with minimal risk.

6. At the end of the loading / unloading operation, the dock leveler is retracted.

7-8-9.The bay operator close the door / barrier, that lowers the chocks automatically. The chocks, when fully lowered allow the lorry to leave.